| Parameter | Range | |

|---|---|---|

| Steel Material | Q235, Q345, S355, ASTM A36/A992, S235/S355 | |

| Building Lifespan | Over 50 years | |

| Seismic Performance | Design seismic intensity: Level 6-9 | |

| Anti-corrosion Treatment | Coating: 120-160μm | |

| Environmental Impact | 100% recyclable | |

| Load Capacity | Design load: 1.5-3 kN/m² (customizable based on requirements) | |

| Construction Period | 2-6 months (depending on project scale and complexity) | |

| Thermal Insulation | Thermal conductivity ≤0.035W/m·K | |

| Wind Resistance | Customized according to local climate conditions | |

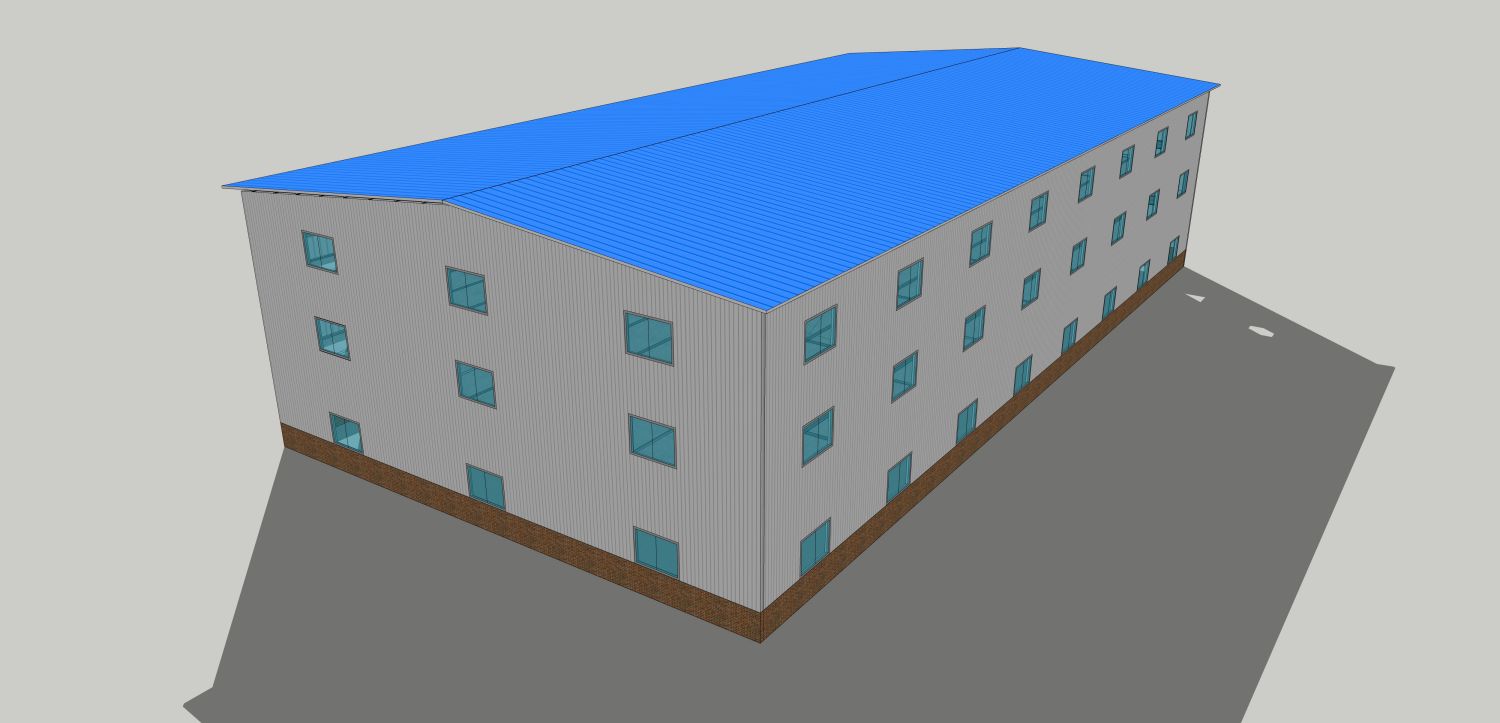

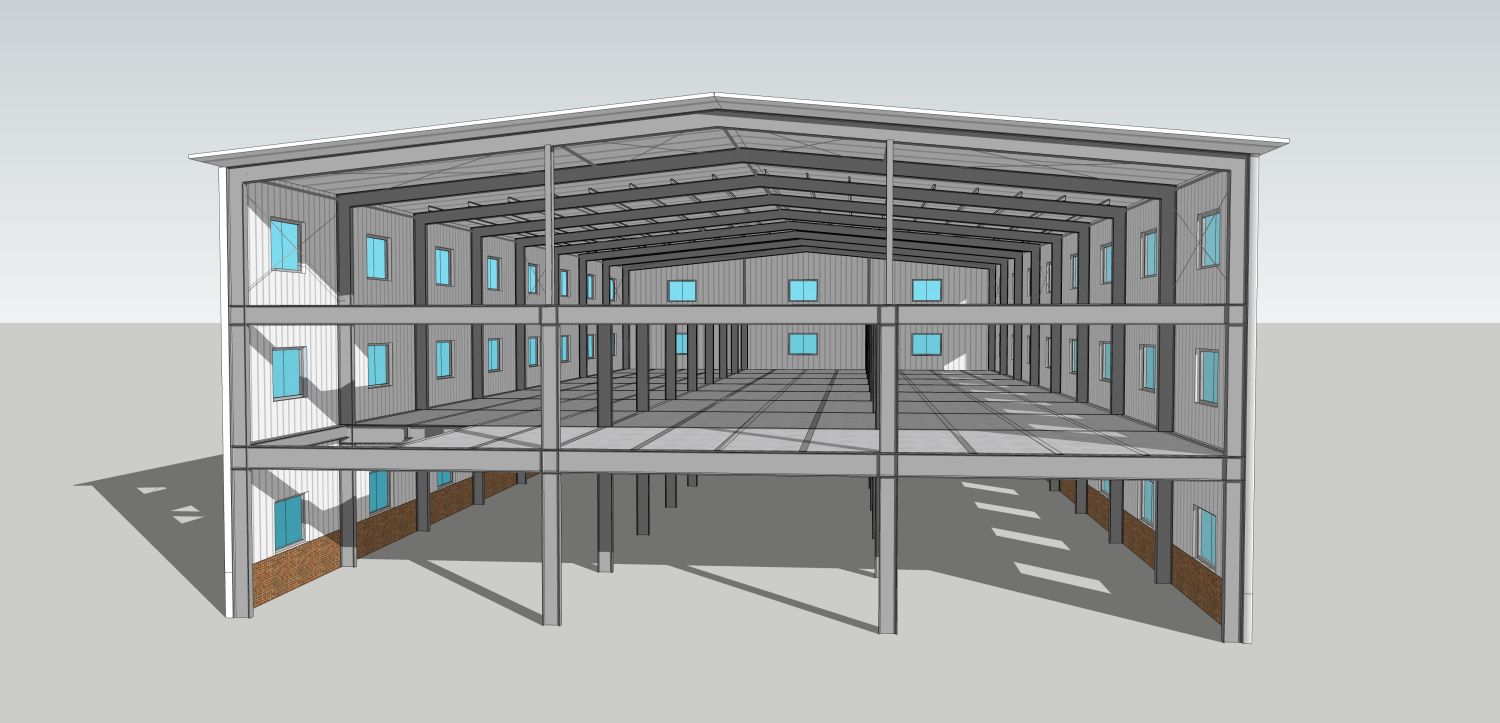

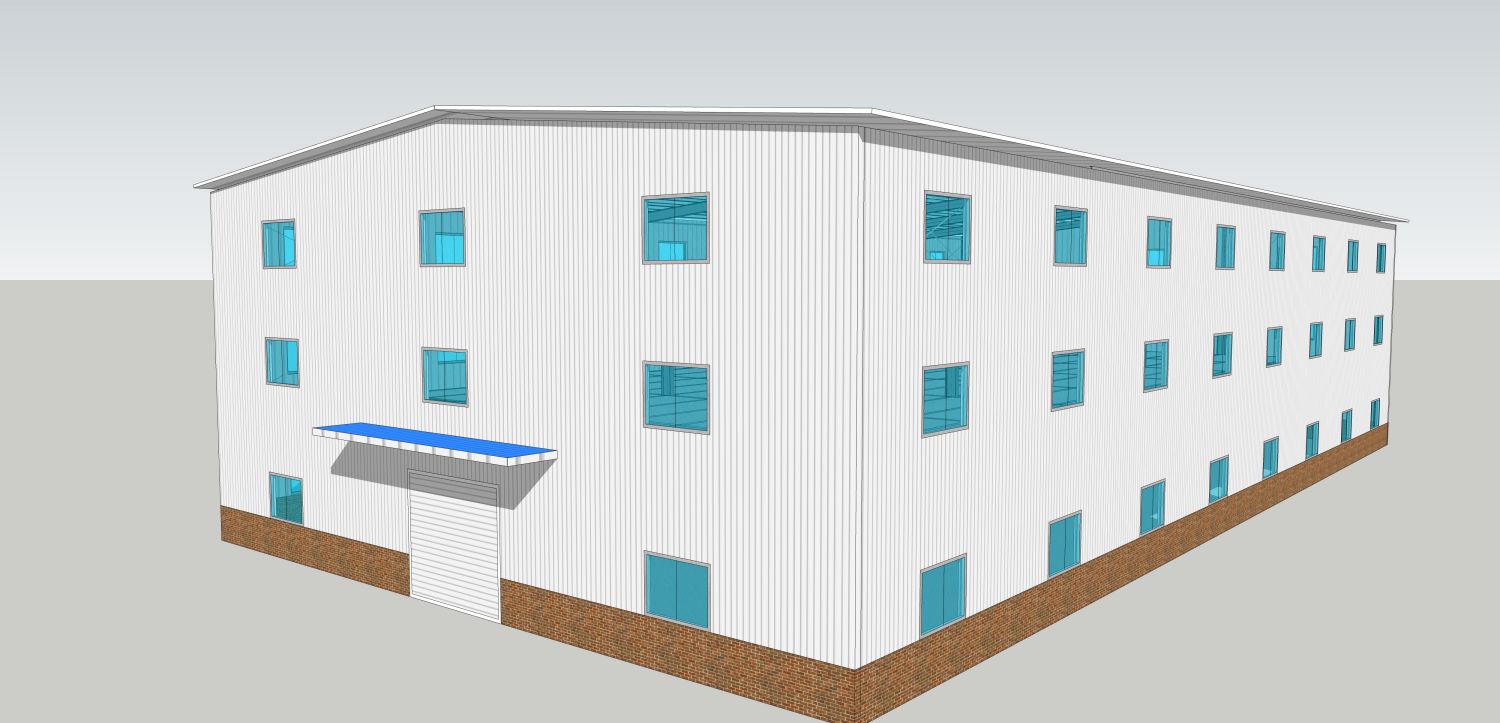

The 50×25 Pre Engineered Buildings are an efficient construction solution produced using advanced pre-fabrication techniques, based on standardized design and modular production methods that significantly shorten construction time and reduce overall investment costs. These pre-engineered buildings (also known as PEBs or Pre-Fab Buildings) provide a spacious, column-free environment, making them ideal for applications such as industrial plants, logistics warehouses, and commercial centers. By completing most of the manufacturing process in a controlled factory setting and only requiring rapid assembly on-site, they ensure high-quality construction and safety, while also allowing for easy future expansion or modification. Whether facing harsh weather conditions or meeting the demands of a fast-paced commercial environment, the 50×25 pre-engineered buildings consistently meet stringent performance requirements, becoming a vital force in driving sustainable development in the modern construction industry.

Recommended Use

Customize Your Steel Structure

Based on your specific needs, we provide comprehensive customized steel structure design and manufacturing services. From structural safety to aesthetics, we ensure every detail meets your project requirements. Whether it’s special sizes, shapes, or functional needs, we tailor the most suitable steel structure solution to help you achieve the best outcome for your project.

Receive a free 3D design for your steel structure project within 24 hours!

Requirement Analysis

We engage in in-depth communication to fully understand your steel structure project requirements, environmental conditions, budget range, and project timeline. We offer professional advice and solutions regarding potential issues such as budget overruns and foundation load-bearing capacity, ensuring a smooth and risk-free steel structure design and construction process.

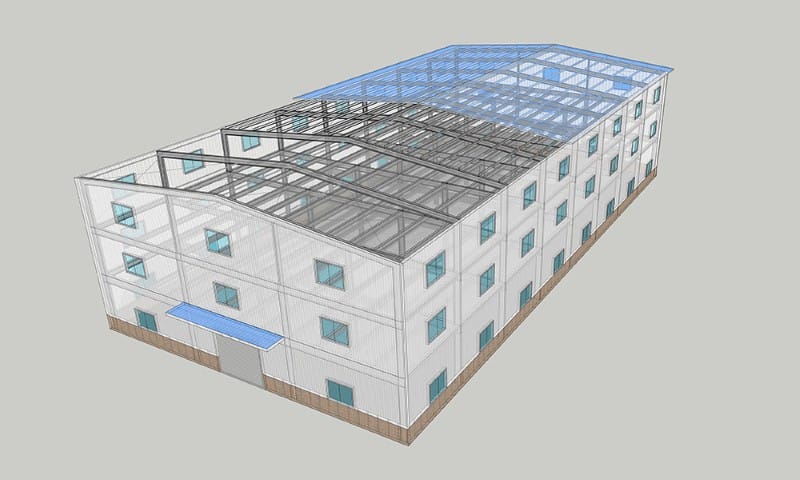

3D Modeling and Detail Optimization

We use advanced modeling software to provide a 3D visualization of the building, transforming 2D drawings into an intuitive visual representation, giving you full insight into the final structure. During the modeling phase, we focus on technical details such as node design, load-bearing analysis, and seismic performance, proactively optimizing potential weak points to ensure safety and stability.

Factory Production and Quality Inspection

We offer factory-based high-precision steel structure component production, covering key processes such as cutting, welding, and corrosion treatment, ensuring quality and precision. We use advanced equipment to conduct strict tests, including weld inspections, dimension verification, and surface coating checks, and provide detailed inspection reports and third-party certifications to ensure every production step meets national and international standards.

Transportation and Installation Guidance

Based on the specific conditions of the construction site, we develop a detailed transportation plan for steel structure components to ensure safety during transit. During installation, to address potential technical challenges, we provide detailed installation manuals and a technical support hotline to assist you in handling unexpected issues, minimizing additional costs and time delays during the installation process.